Call 724-253-2771

Get a free quote or Design Your Building

Want to see if a Gold Star building is right for you? Get a FREE quote or use our 3D Builder to design your own shed, garage, or cabin!

Perhaps you’ve never considered it, but the shed flooring may be the most important part of your shed. After all, it’s technically the part of your shed that gets used the most. If your shed floor is in weak or in poor condition, your shed is essentially useless.

In this article, we discuss the best options for shed sub-flooring as well as great options for finished shed flooring. Whether you’re looking to buy a new shed or upgrade the shed flooring of a building you already own, our aim is to leave you better informed about your options when it comes to shed flooring.

Table of Contents

The subfloor of your shed is a crucial part of the shed structure. Having a solid subfloor will give you the ability to store heavy items like tractors, as well as heavy gym equipment if you use your shed as a home gym. Here are some of the best options for your shed sub-flooring.

Pressure-treated plywood is one of the most common shed flooring options, and for good reason. ⅝ ” to ¾” plywood is the most common subflooring shed builders use since plywood that’s been pressure-treated is resistant to moisture and rot and will last for quite a long time. It also features a smooth finish that’s easy to sweep and clean. This style of flooring also makes it easy to install carpet and vinyl planking, making it a great choice for finished sheds.

Plywood Shed Flooring Pros:

Plywood Shed Flooring Cons:

If you’re looking for great plywood flooring options, check out LP Building Solutions.

OSB is one of the cheapest subfloor options, and is typically seen as a lower cost alternative to plywood. It isn’t quite as strong as plywood, and typically doesn’t hold up to moisture as well as plywood. However, if you’re looking for a low-cost flooring option and don’t mind how it looks, OSB could be a viable option.

OSB Shed Flooring Pros:

OSB Shed Flooring Cons

Using composite decking as a shed floor without any additional subfloor is not a popular option, but can be a good choice in certain situations. Composite deck boards are quite durable and are very moisture resistant.

If you plan to use your shed in a way that requires it to be washed regularly, the gaps between the deck boards would allow the water to drain away. Deck boards, however, aren’t as rigid as plywood, so it would be a good idea to add extra runners to support the flooring.

Composite Deck Boards Pros

Composite Deck Boards Cons

For some composite deck board options, check out Home Depot or Lowe’s.

The strongest flooring option is to simply use a concrete slab as the flooring. In terms of strength and durability, nothing beats concrete. It can be expensive, but since the concrete can be both the shed foundation and the flooring, it can be a cost effective option.

To use concrete as the shed floor, the shed is essentially fastened to the concrete pad which makes the shed unmoveable. Some people may see this as a downside, but it also makes the shed quite sturdy.

Concrete Shed Flooring Pros

Concrete Shed Flooring Cons

Many shed owners simply leave their shed subflooring exposed since sheds are typically used as storage or as workshops. However, more and more people are choosing to finish our their sheds and use them as living spaces or home office. Here are a few great finished shed flooring options:

The easiest and cheapest way to finish your shed floor is to paint or stain it. This is easiest if your shed flooring is wood, but concrete can also be stained. Not only does paint improve the look of a shed interior, but it also helps protect the flooring, especially if the shed flooring is made from untreated wood.

Painted or Stained Flooring Pros

Painted or Stained Flooring Cons

Vinyl plank flooring is one of the most popular flooring options for a variety of living spaces, including homes, offices, and finished sheds. This vinyl plank flooring both looks great and is quite durable. Vinyl planking, however, is susceptible to temperature fluctuations, and should only be used if your shed is climate controlled.

Vinyl Plank Flooring Pros

Vinyl Plank Flooring Cons

Vinyl planking can be found at most large hardware stores as well as stores such as Decks Direct.

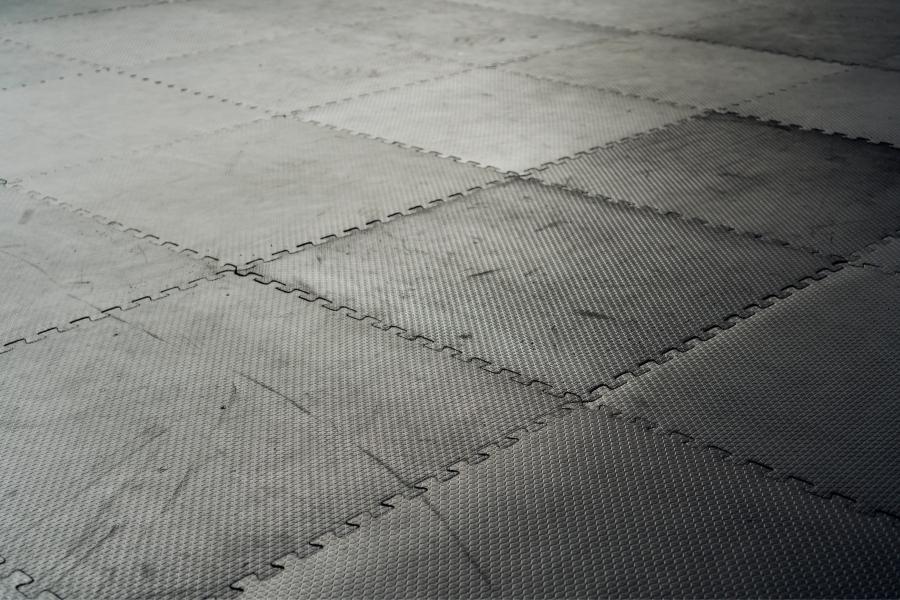

Rubber tiles are popular in garages and gyms, but can also be used in sheds. Rubber tiles offer both durability and protection for the subfloor, but also make a floor a bit more soft and forgiving than bare wood.

Rubber Tile Flooring Pros

Rubber Tile Flooring Cons

For some great rubber tile flooring options, check our Rubber Flooring Direct.

Epoxy can be applied to both concrete and wood flooring, and is a great way to upgrade the look and durability of a shed floor. This type of finish is relatively easy to apply and is popular with DIyers.

Epoxy Flooring Pros

Epoxy Flooring Cons

For more information on epoxy flooring, check out this article from Sherwin-Williams.

One of the easiest ways to upgrade a shed interior is by adding carpet. Carpet is a great choice if you happen to have some extra material from another project or love the warm feel of carpet. However, carpet isn’t the most durable choice and isn’t the best option for work shop sheds

Carpet Flooring Pros

Carpet Flooring Cons

Not all sheds need to have an insulated floor, but if plan heat your shed, it’s probably a good idea. If you plan to finish out your shed and add heating and cooling, your shed floor should be insulated.

Keep in mind that some shed flooring options, like vinyl planking and epoxy finishes, are best used if the shed is climate-controlled and the floor is insulated. Below are a few popular shed floor insulation options.

Spray foam insulation is the most popular shed floor insulation option, and the best overall choice. It’s the most durable and provides great R-value, even in small spaces. However, it isn’t the cheapest option and it requires a sprayer to apply.

Batt insulation is one of the easiest types of insulation to install and is popular with DIYers. It’s also a low cost option. It isn’t quite as effective a spray foam and isn’t as durable.

Foam board insulation is applied by cutting the board to a specific size and adding the board between the shed floor joists. This makes the installation a bit more tedious than the other options as the pieces need to be precisely cut. However, it’s still a good option and relatively low cost.

Whether your buying a new shed or are upgrading the floor of an existing shed, it’s important to have a shed floor that’s both durable and serves your needs. We hope this article gives you the information you need to make a great choice for your next shed floor. Feel free to reach out to us with any questions you have about shed flooring or other questions about our sheds.

Want to see if a Gold Star building is right for you? Get a FREE quote or use our 3D Builder to design your own shed, garage, or cabin!